Overview.

Fast acting fire suppression with HFC-227ea

HFC-227ea fire suppressant is widely accepted and respected around the world, with a history of protecting the world's most crucial and irreplaceable assets. It’s used in thousands of applications—including cultural property, data centers, and critical infrastructure—across more than 70 countries.

HFC-227ea gaseous fire suppression systems offer exceptionally fast fire protection, reaching design concentrations in ten seconds or less. They stop ordinary combustible, electrical, and flammable liquid fires before they cause significant damage, and are safe for use around people.

The ability to extinguish a fire within seconds means:

- Less damage

- Lower repair costs

- Extra margin of safety for people

- Less downtime and disruption of business

Trade Names.

FM-200, FE-227

Chemical Composition.

Chemical Name - Heptafluoropropane

Chemical Formula - CF3CHFCF3

Gas Specification.

The gas specification is usually confirmed with a certificate of conformity (COC) from the manufacturer. It’s also important to ensure each specification is maintained during the 10-year testing and a new COC is provided confirming each requirement below by your supplier for the new re-filled or re-tested agent.

| Property | Specification Limits |

|---|---|

| Purity | 99,6% mol/mol min. |

| Acidity | 3 × 10–6 by mass, max. |

| Water Content | 10 × 10–6 % by mass, max |

| Non-Volatile Residue | 0,01% by mass, max. |

| Suspended matter or sediment | None visible |

Physical Properties.

| Property | Units | Value |

|---|---|---|

| Molecular mass | n/a | 170 |

| Boiling point at 1,013 bar (absolute) | °C | -16.4 |

| Freezing point | °C | -127 |

| Critical temperature | °C | 101.7 |

| Critical pressure | bar | 29.26 |

| Critical volume | cm3/mol | 274 |

| Critical density | kg/m3 | 573 |

| Vapour pressure 20 °C | bar abs | 3.9 |

| Liquid density 20 °C | g/ml | 1410 |

| Saturated vapour density 20 °C | kg/m3 | 31.035 |

| Specific volume of superheated vapour at 1,013 bar and 20 °C | m3/kg | 0.1374 |

Design Concentrations.

| Standard | Class A | Higher Hazard Class A / Class C | Class B |

|---|---|---|---|

| (BS) EN 15004 | 7.9% | 8.5% | 9.0% |

| NFPA 2001 | 6.7% | 7.0% | 8.7% (n-heptane) |

| APSAD | 7.9% | N/A | Subject to hazard |

Loael, Noael & Minimum Safety Precautions.

The below is based on the requirements of EN 15004 which is the most common design standard in the UK and other European areas.

| Property | Value |

|---|---|

| No observed adverse effect level (NOAEL) | 9.0% |

| Lowest observed adverse effect level (LOAEL) | 10.5% |

| Concentration | Time delay device* | Automatic / Manual Switch** | Lock-off device*** |

|---|---|---|---|

| Up to and including the NOAEL | Required | Not Required | Not Required |

| Above the NOAEL and up to the LOAEL | Required | Required | Not Required |

| LOAEL and above | Required | Required | Not Required |

* Time delays are usually integrated within the main gas extinguishing panel to allow a 30 second delay before the system discharges. Hold off buttons are also usually located adjacent the exits of the enclosure.

** Automatic / Manual switches are usually integrated into the main gas extinguishing panel located at the entrance of the protected area.

*** Lock-Off devices are usually manual isolation valves installed within the pipework and again located at the entrance of the protected area.

HFC-227ea Quantity Calculation.

Typically, gaseous extinguishing systems are used for protecting electronic equipment in data rooms or similar, we have therefore prepared a quick calculation to help understand and estimate the quantity HFC-227ea agent required in your enclosure. The factor provided below is also based on a design temperature of 20°C and an altitude of 0, changes in either will have a small effect on the agent quantity.

Design Concentration = 8.5% (Higher Hazard Class A)

Flooding Factor = 0.6773

Volume of enclosure in M³ x Flooding Factor = Quantity required in KG

[Example assuming room volume of 150m³]

150 x 0.8253 = 101.595kg

For a calculation spreadsheet in excel format or for quantity calculations outside of these parameters, please contact us directly at

hello@mepfire.com.

Typical Cylinder Fill Weights, Sizes, Pressures & Quantity Calculator.

HFC-227ea cylinders come in a variety of sizes depending on the manufacturer but below we have presented an example list of a manufacturer’s sizes.

As a general rule, cylinders can be filled to a maximum of 90% of their volume or a minimum of 40% of their volume in Kg.

| 15 Litres | 30 Litres | 50 Litres | 80 Litres | 120 Litres | 150 Litres | 180 Litres | |

|---|---|---|---|---|---|---|---|

| Maximum Fill | 13.5kg | 27.0kg | 45.0kg | 72.0kg | 108.0kg | 135.0kg | 162.0kg |

| Minimum Fill | 6.0kg | 12.0kg | 20.0kg | 32.0kg | 48.0kg | 60.0kg | 72.0kg |

Typically, cylinders are pressurised to 25, 42 or 70 bar.

By using the quantity calculation above, and the maximum fill of each cylinder above, you can work out how many cylinders are typically required for your protected area.

Environmental Considerations.

HFC-227ea has a global warming potential of 3500 and an atmospheric lifetime of 33-36.5 years. HFC-227ea is also being phased out under the F-Gas Regulation which is why it’s use is becoming less and less common. However, its properties are favourable when compared with older agents such as Halon 1301.

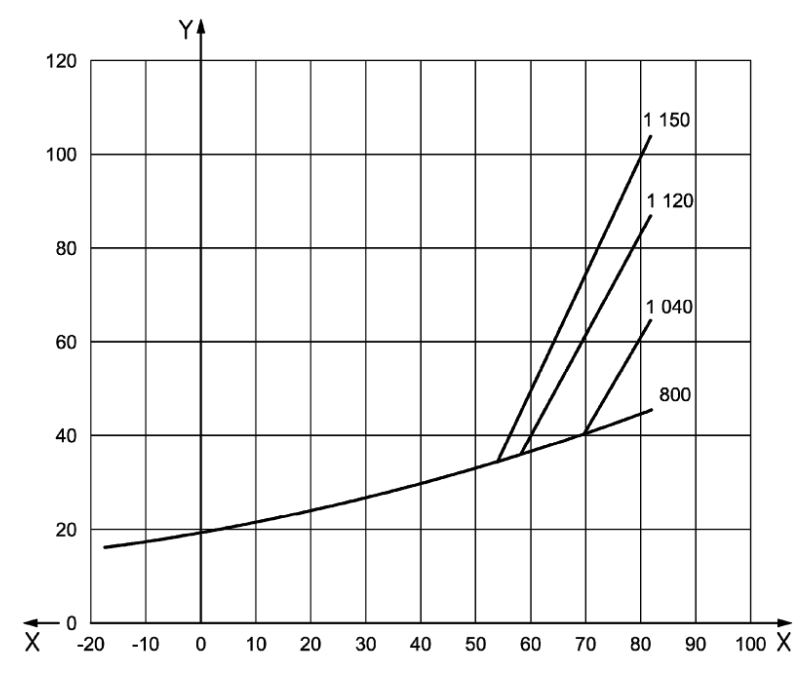

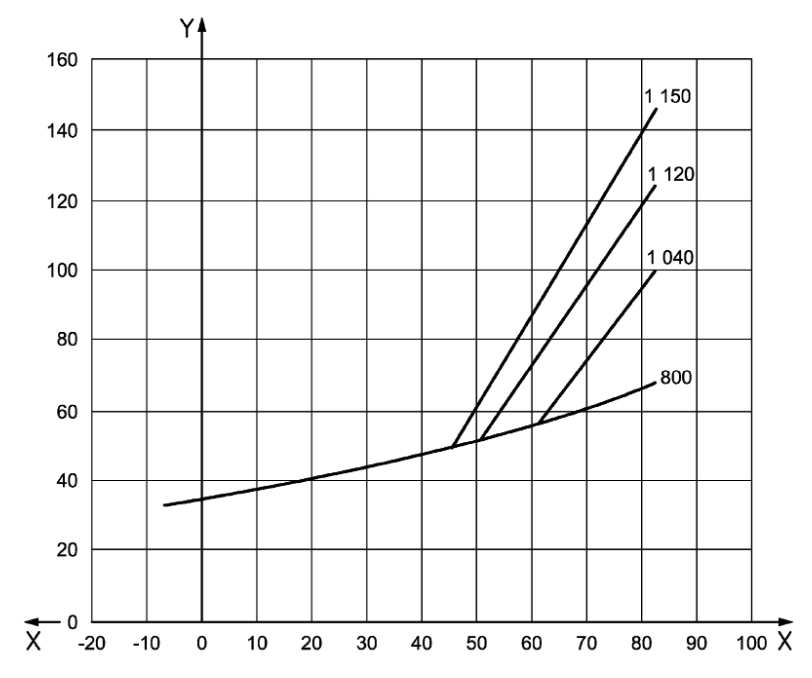

Temperature Vs Pressure Graphics

Temperature graphs are useful for verifying the pressure or your cylinders and whether they need replacing in line with the recommendations of BS EN 15004 which advises:

Liquefied gases: for halocarbon agents, if a container shows a loss of agent in quantity of more than 5% or a loss of pressure (adjusted for temperature) of more than 10%, it shall be refilled or replaced.

Temperature/pressure graph for HFC-227ea at 25 bar @ 20°C

Temperature/pressure graph for HFC-227ea at 42 bar @ 20°C